Water can do some pretty wonderful things – especially when it comes to the world of medical device reprocessing. But how much do you know about how, when, and where water quality impacts workflows in Sterile Processing and patient safety in the Operating Room? On this new 3 CE approved series, “The Wonderful World of Water Quality,” our education team at IST will walk you through the basics of this important topic, highlight important technical know-how, and give you concrete steps for improving the water quality in your department.

You won’t need a snorkel and swimsuit to join us for this water party, instead grab a notebook and your department manager and let’s get to it!

Water Quality Requires Collaboration

Water quality is an important consideration in all stages of medical device reprocessing and getting it right requires collaboration between the personnel who reprocess medical devices and the personnel who establish and maintain the water treatment system. Water quality teamwork, makes the water quality dream work!

Water can be treated by a variety of methods that yield different levels of water quality. Gram-negative bacteria and nontuberculous mycobacteria can grow in any type of water, including tap, softened, deionized (DI), reverse osmosis (RO) treated, and distilled water. The rate of growth and the

microbial levels attained are a function of the amount of organic contaminants in the water. The importance of monitoring water quality to prevent problems with microbial overgrowth cannot be overemphasized.

One of the most common breakdowns in water quality is when various teams (i.e. Sterile Processing & Facilities) are not talking to each other, thus leaving the door open for a process breakdown.

Whose Responsibility is Your Water?

Water quality is a team sport. But even team members have different responsibilities for different parts of the mission – and the same is true in medical device reprocessing in the healthcare setting. “Who does what?” is a common question that comes up whenever this issue is raised, so it’s important to have a good understanding of where certain duties reside prior to “going live” with new equipment or hiring new personnel.

Sterile Processing personnel considerations

Device reprocessing personnel should receive education, training, and competency verification in the importance of water quality, the patient risks associated with improper water system characteristics, and the water quality monitoring that should be performed in reprocessing areas.

Water maintenance personnel

Water maintenance personnel should receive education, training, and competency verification in the maintenance and monitoring of water treatment equipment. All personnel training should be specific to the functions performed.

Periodic audits of personnel compliance with policies and procedures should be performed.

Assessing & Implementing Water Quality

To provide optimal water for medical device reprocessing, reprocessing personnel and water maintenance personnel should collaborate with administrative personnel to implement the following procedures:

Procedure 1: Assessment of Water Quality

What to Do

The tap water from the public utility source should be analyzed by an accredited facility with expertise in water quality to determine whether the water requires treatment and, if so, what type of treatment. This analysis should take into account seasonal variations in water quality.

Who is Responsible

Water maintenance personnel.

Procedure 2: Implementation of Water Treatment Process

What to Do

On the basis of the assessment in Step 1 and in consultation with an accredited facility with expertise in water quality, personnel should ensure that treatment processes are implemented to provide the type of water quality needed for the medical device reprocessing needs of the facility.

Who is Responsible

Water maintenance personnel in conjunction with device reprocessing personnel.

Stay tuned for additional procedures on the next post in this series!

Assurance and Monitoring of Water Quality

As discussed in the previous series post, in addition to enacting assessment (#1) and implementation (#2) procedures for water quality as a collaborative team, your Sterile Processing, facility, and administrators should also implement the following procedures:

Procedure 3: Assurance of Proper Water Quality for the Various Stages in Medical Device Reprocessing

What to Do

Medical device reprocessing areas should be audited to determine whether water of the correct quality is being used for the devices being reprocessed in each area. If not, the water treatment should be modified as necessary.

Who is Responsible

Device reprocessing personnel in conjunction with health care technology management personnel

Procedure 4: Ongoing Monitoring of Water Quality

What to Do

Where applicable, monitoring procedures should be established to ensure that the treated water is of adequate quality for medical device reprocessing. Water maintenance personnel and device reprocessing personnel should communicate effectively to ensure that action is taken when inadequate water quality is detected.

Who is Responsible

Water maintenance personnel in conjunction with device reprocessing personnel

Utility vs. Critical Water

You’ve probably heard these terms before during an inservice, conference presentation, or while studying for your certification exam, but would you be able to explain the difference between “utility water” and “critical water” if a surveyor asked you about them? Don’t sweat it. We’ve got you covered.

Utility Water: Water as it comes from the tap that might require further treatment to achieve the specifications. This water is mainly used for flushing, washing, and rinsing. The decision regarding the need to treat incoming tap water to provide adequate water for medical device reprocessing should be undertaken in every facility that reprocesses medical devices.

Critical Water: Water that is extensively treated to ensure that the microorganisms and the inorganic and organic material are removed from the water. This water is mainly used for the final rinse or steam generation.

It should be noted that steam quality is affected by the quality of the incoming water. Pretreatment of the incoming water might be needed to ensure that the steam produced does not cause deposition of residuals when used for steam sterilization of medical devices.

AAMI Standard vs AAMI TIR?

Do you know the difference in an AAMI Standard document and a TIR?

All standards, recommended practices, technical information reports (TIR), and other types of technical documents developed by AAMI are voluntary, and their application is solely within the discretion and professional judgment of the user of the document. Occasionally, voluntary technical documents are adopted by government regulatory agencies or procurement authorities, in which case the adopting agency is responsible for enforcement of its rules and regulations.

Standards are subject to a formal process of committee approval, public review, and resolution of all comments. A TIR is not subject to the same formal approval process as a standard. However, a TIR is approved for distribution by a technical committee and the AAMI Standards Board.

A TIR may be developed because it is more responsive to underlying safety or performance issues than a standard or recommended practice, or because achieving consensus is extremely difficult or unlikely. Unlike a standard, a TIR permits the inclusion of differing viewpoints on technical issues.

Water Quality and Device Malfunction

The primary objective of medical device reprocessing is to ensure that a device is SAFE for patient use and does not cause an adverse event in the patient. The overall goals of water treatment in medical device reprocessing are to prolong the life of medical instrumentation, to ensure effectively functioning instrumentation, and, more importantly, to help minimize the risk of adverse patient outcomes arising from contaminated medical devices.

In other words, in order for device reprocessing to be safe, effective, and efficient, water treatment must be safe, effective, and efficient as well.

Device malfunction during a patient procedure (e.g., corrosion of a surgical instrument because of salt or other water deposits) could result in breakage of the device inside the patient when stress is applied to the device or mechanical movement of the device could be obstructed by residual debris inside the mechanism because of inadequate cleaning stemming from inactivation of the detergent by water of improper quality.

Whatever the particular cause of subpar water quality, we owe it to our patients to get it right.

Water Quality and Toxic Effects

Toxic effects and tissue irritation can result from residuals on a device or implant that was reprocessed using water of inadequate quality. For example, pyrogenic reactions could occur as a result of high levels of endotoxin or other pyrogenic agents left as residuals from water that contained high microbial levels. Or residual salts from water used for the final rinse could be converted by ethylene oxide to toxic residues.

As medical device reprocessors, the last thing we want to do is potentially bring harm to a patient under our care. Even though it may be easy to forget the potential harm that is present in our department water sources, we should constantly be aware of that threat and ensure that the department water quality plan is being implemented and audited on a regular basis.

Water Quality and Patient Infections

Did you know that patient infections can result from the use of devices reprocessed with inadequate water quality?

If salt or organic deposits from the water is not removed prior to reprocessing, these things could inactivate the disinfectant or sterilant, or could protect microorganisms from the disinfection or sterilization process.

Likewise, disinfected or sterilized devices could transmit an infection if rinsed with water containing unacceptable levels of microorganisms. This would be an example of cross-contamination in a reprocessing workflow.

With all the focus we place on proper equipment, supplies, and training in the Sterile Processing industry, don’t forget the potential for inadequate water quality to undermine the entire process. While it is true that “If it’s not clean, it can’t be sterile,” the water quality used to get devices “clean” is just as important as the brushes, washers, and technique used by our team members. Without safe water, nothing else matters.

Water Quality and Ineffective Cleaning/Disinfection

As we mentioned in the previous post, inadequate water quality can impact patient safety and undermine the cleaning process itself. But how does this happen?

Chemical integration with water contaminants causes water contaminants to bind with the detergent surfaces, preventing them from dispersing soils. Thus the basic science of cleaning is unable to do its critical work of removing gross bioburden from the surgical instruments we have flowing through decontamination. If contaminated soil is not removed, all manner of pathogens can remain on the medical device as it continues on through the reprocessing workflow.

A good way to think about this is to consider the game of football. Detergents are the offense, and they want to score a touchdown by loosening up the soil and debris on a contaminated medical device. However, contaminates in our water can act as defense, and block the detergent from making progress in the cleaning process. On the other hand, with appropriate water quality, the offense is able to score much easier, since the detergent has less interference blocking their way. Touchdown!

Microbial Levels in Water

Water in a reprocessing department should not increase the bioburden of the devices being processed, from stage to stage. When water comes into a hospital from public utility, it is usually chlorinated to prevent microbial replication. Even in chlorinated water, however, the level of microorganisms depends on the effectiveness of the municipal treatment process and on the state of the distribution system. In addition, chlorinated water might contain other inorganic components that will damage medical devices during reprocessing, thereby necessitating water treatment, such as deionization (DI), to remove these components.

But there is a downside. Such treatment (such as DI) will also remove the chlorine; consequently, any microorganisms present will have a significantly greater ability to replicate.

Alternative water treatment processes, such as reverse osmosis (RO), will remove microorganisms as well as inorganic components, thereby reducing the microbial load in the water. However, the RO system could become contaminated with microorganisms and subsequently develop biofilm on the inner surfaces of the piping.

Our next post will highlight water characteristics that pose a risk.

Water Challenges: Bacterial Endotoxins

A number of different water challenges contribute to unacceptable organic and inorganic levels. The first one we will cover in this series is bacterial endotoxins.

Bacterial endotoxins are organic compounds that are derived from the cell walls of bacteria and that, when introduced into the human body, can cause a fever-like (pyrogenic) reaction and other adverse effects. Unlike microorganisms, endotoxins are not reliably destroyed by disinfection or sterilization processes. Therefore, if the incoming water used for cleaning and rinsing has high levels of endotoxins, residual endotoxins might remain on reprocessed devices.

If water control strategies are faulty and the system is not prospectively monitored, it is possible that rinse water could have high enough endotoxin concentrations that residuals on a medical device might result in an adverse patient reaction, depending on the body site with which the device has contact. Residual endotoxins are a concern for medical devices that will contact the patient’s bloodstream, cerebrospinal fluid, or the anterior chamber of the eye.

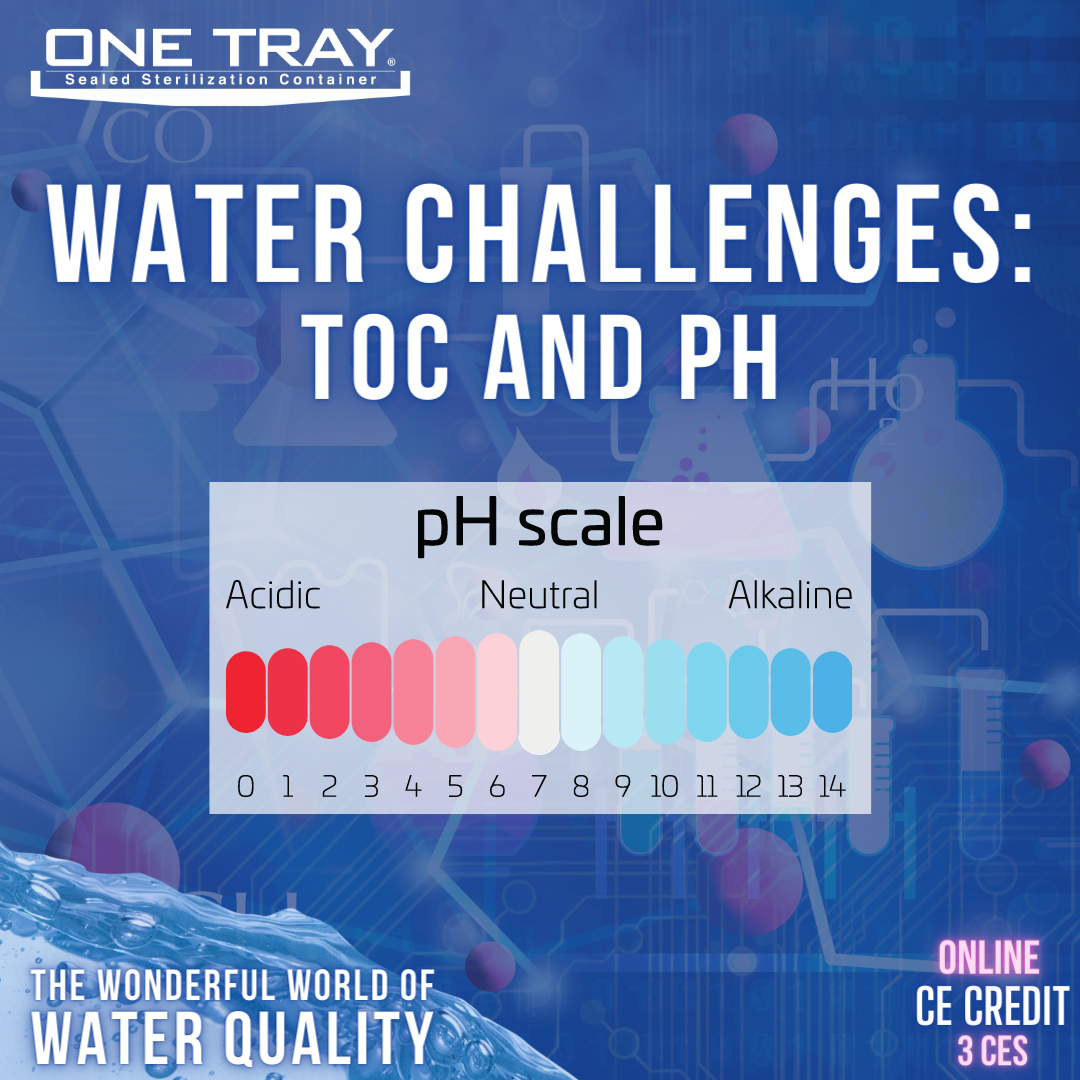

Water Challenges: TOC & pH

In additional bacterial endotoxins (which we covered on the last post), total organic carbon (TOC) and pH can also negatively impact the quality of water in your Sterile Processing department.

The presence of organic carbon is an indication that the water contains material derived from living sources or organic pollutants (e.g., microorganisms, plants, animals, pesticides). Water that is contaminated or overgrown with microorganisms will have a high TOC level. If water with a high TOC level is used in device reprocessing, water residuals can discolor the device and interfere with the effectiveness of detergents, disinfectants, or sterilants. Also, high organic carbon levels provide nutrition to microorganisms and can contribute to microbial overgrowth in the water.

The pH of water used in device reprocessing can directly affect the medical device by causing pitting or corrosion. The pH can also indirectly affect the device by interfering with the effectiveness of the detergents (especially enzymatic detergents), disinfectants, or sterilants used in reprocessing (i.e., the water pH is not compatible with the detergent, disinfectant, or sterilant).

Water Challenges: Hardness and Temperature

Have you ever seen white film or crust develop in or on your reprocessing equipment? If so, you have likely seen the results of hard water.

Water hardness is caused by the presence of dissolved salts (typically calcium and magnesium) that deposit as hard mineral layers (lime-scale) when the water is heated or evaporated. Very hard water can decrease the effectiveness of most detergents and disinfectants; for example, components of hard water bind with detergent surfactants, preventing them from dispersing soils. Very hard water can also adversely affect the performance of medical washers and medical washer–disinfectors.

Water temperature is another important consideration as it can have a significant impact on the effectiveness of reprocessing. The temperature of the water affects the efficacy of precleaning, cleaning, rinsing, liquid chemical disinfection, and liquid chemical sterilization. In general, the appropriate temperature depends on the stage of reprocessing, as well as the medical device, cleaning agent, and cleaning equipment manufacturers’ written IFU.

Water Challenges: Ions and Resistivity

Grab your pocket protector and push your glasses back up your nose for this one, because we’re getting into the real science of cleaning here! Let’s talk ions and resistivity in water.

An ion is an electrically charged atom or molecule. The ions of importance in water for medical device reprocessing are:

-chloride

-iron

-copper

-manganese

But how do these ions impact our equipment and surgical instrumentation? Glad you asked.

Excessive chloride can cause corrosion pitting. Excessive iron, copper, or manganese (called heavy metal ions) can tarnish stainless steel instruments (i.e., cause blue, brown, or iridescent surface coloration). Pitting causes a rough surface that prevents adequate cleaning and allows microorganisms and organic material to accumulate, which, in turn, can cause adverse patient effects.

Resistivity in water is the ability of water to resist an electrical current, which is directly related to the amount of dissolved salts in the water. Water with a high concentration of dissolved salts will have a low resistivity, and vice versa.

Manual Precleaning & Cleaning

How should you think about water in the context of manual precleaning and cleaning?

Utility water is suitable for precleaning and rinsing a device immediately after patient use to remove gross debris. To prevent coagulation of blood and other proteins, the temperature of this water should not exceed 113° F.

For the manual cleaning stage, tap water may be used if it meets the requirements for utility water and its characteristics are compatible with the cleaning agents used for medical device reprocessing (as per the manufacturer’s written IFU). It is important that the incoming tap water be analyzed to determine its characteristics and allow the user, in consultation with the detergent manufacturer, to ensure that a compatible detergent is used. It might be necessary to use treated water for the cleaning stage if the tap water in the area is incompatible for use with the detergents recommended for medical device reprocessing.

The need for treated water in this stage varies from location to location, so the water treatment system manufacturer should be consulted to ensure that the treatment process will be adequate for the specific characteristics of the incoming tap water.

Manual Cleaning: Rinsing

On the previous post in this series, we addressed water considerations for manual precleaning and cleaning. Now we’ll turn our attention to the rinsing stage. Tap water is often adequate for rinsing and removing soil loosened by the cleaning process and for rinsing and removing detergent residues, provided that it meets the requirements for utility water. However, if the quality of the tap water could cause corrosion, tarnishing, or salt deposits, it might be necessary to use various water treatment processes (e.g., softening, deionization) to ensure that devices are not damaged and that the ensuing disinfection or sterilization process will be effective.

For devices that will contact the bloodstream or other sterile areas of the body, the final stage in rinsing requires water that does not have excessive levels of organics; therefore, critical water is recommended.

If you attempt to use two different sources of rinse water for different levels of devices, it is imperative that your department have the faucets clearly and properly labeled to ensure staff can easily identify the proper water source for each device.

Mechanical Cleaning

Unlike with manual cleaning, where staff see and work in the water itself, mechanical cleaning functions occur inside automated units, making it much easier to underestimate the importance for the quality of water going into those devices. To achieve the cleaning and decontamination results originally validated by the manufacturer, water quality is important in all stages of the cleaning, decontamination, and disinfection process.

Medical washers and medical washer–disinfectors are equipped with at least one control valve for hot water and one control valve for cold water. A separate control valve for incoming treated water is standard on some models and an option on others. The parameters of each treatment stage within a given cycle can vary depending on the medical devices to be processed.

All treatment stages require water, and utility water is the minimum acceptable quality. At each treatment stage, the water quality should be compatible with:

- The materials of construction of the medical washer or medical washer–disinfector,

- The items being processed,

- The cleaning agents used,

- The disinfectants used, and

- The process requirements at each stage.

Series Summary Post

As we wrap up this Wonderful World of Water Quality series, we want to thank you for tuning in for this CE approved education program. It is important to recognize that in most facilities water treatment is an entire process, not just one water treatment component. The functionality of this process cannot be ensured if the water characteristics are not monitored on an ongoing basis.

If at any time your monitoring indicates that the water is not of the quality expected, then this information should be effectively communicated to the device reprocessing personnel to ensure that patients are not put at undue risk as a result of the water treatment problem. In addition, corrective actions should be taken immediately to rectify the problem and to ensure that the proper water quality is made available for medical device reprocessing. It is essential that an ongoing monitoring program be implemented and that corrective actions be taken when water quality deteriorates.

Water Quality Definitions

For your reference, here is a comprehensive list of sourced definitions that were used throughout the course.

PDF