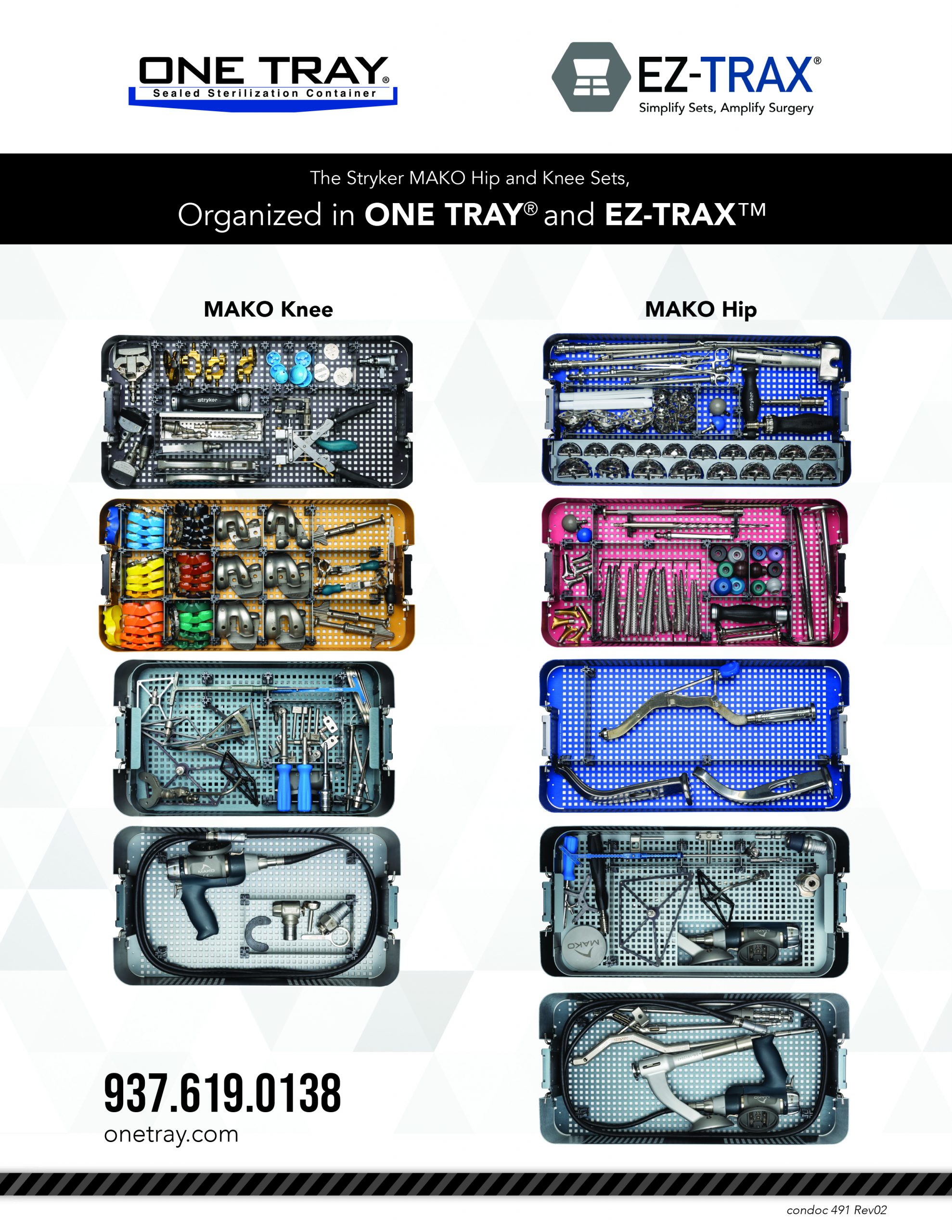

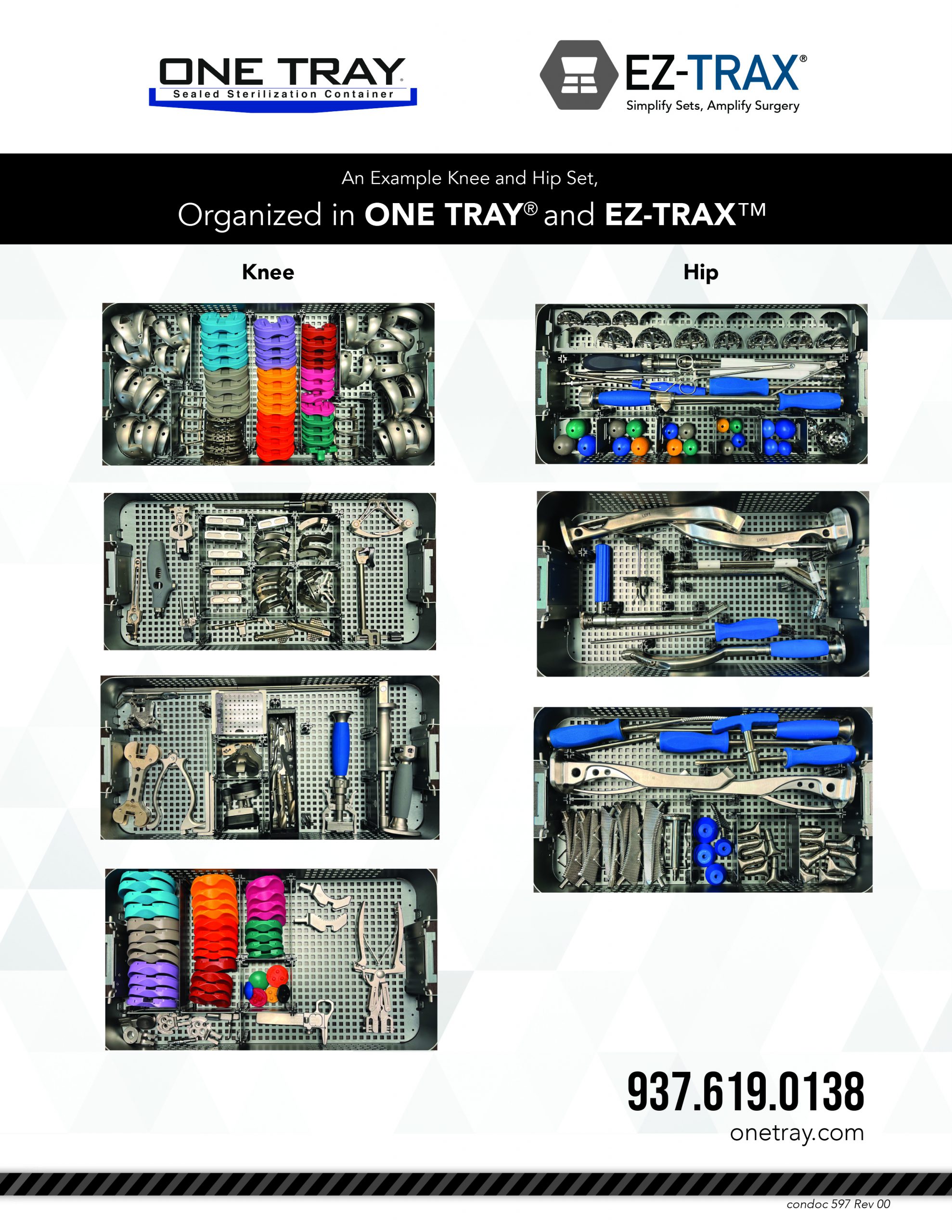

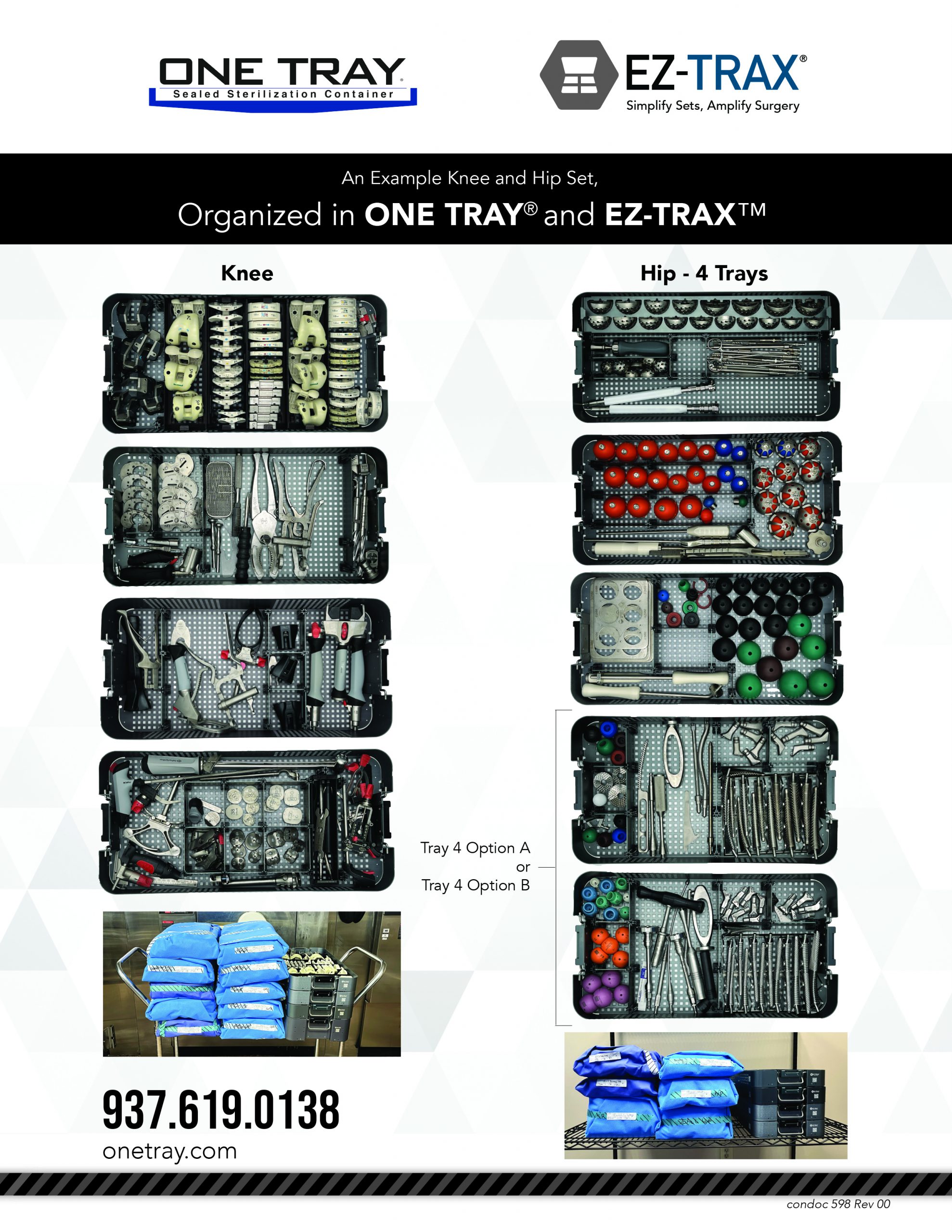

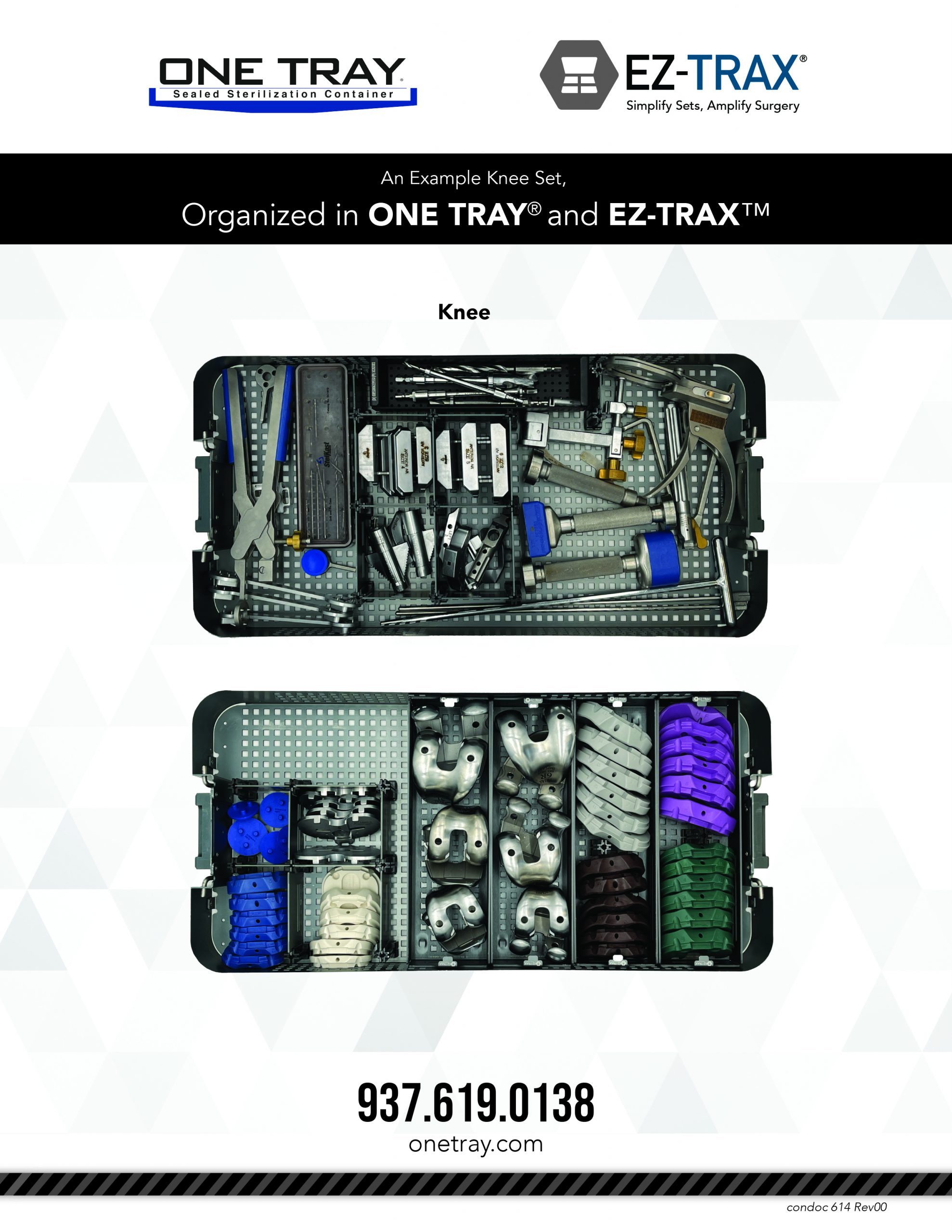

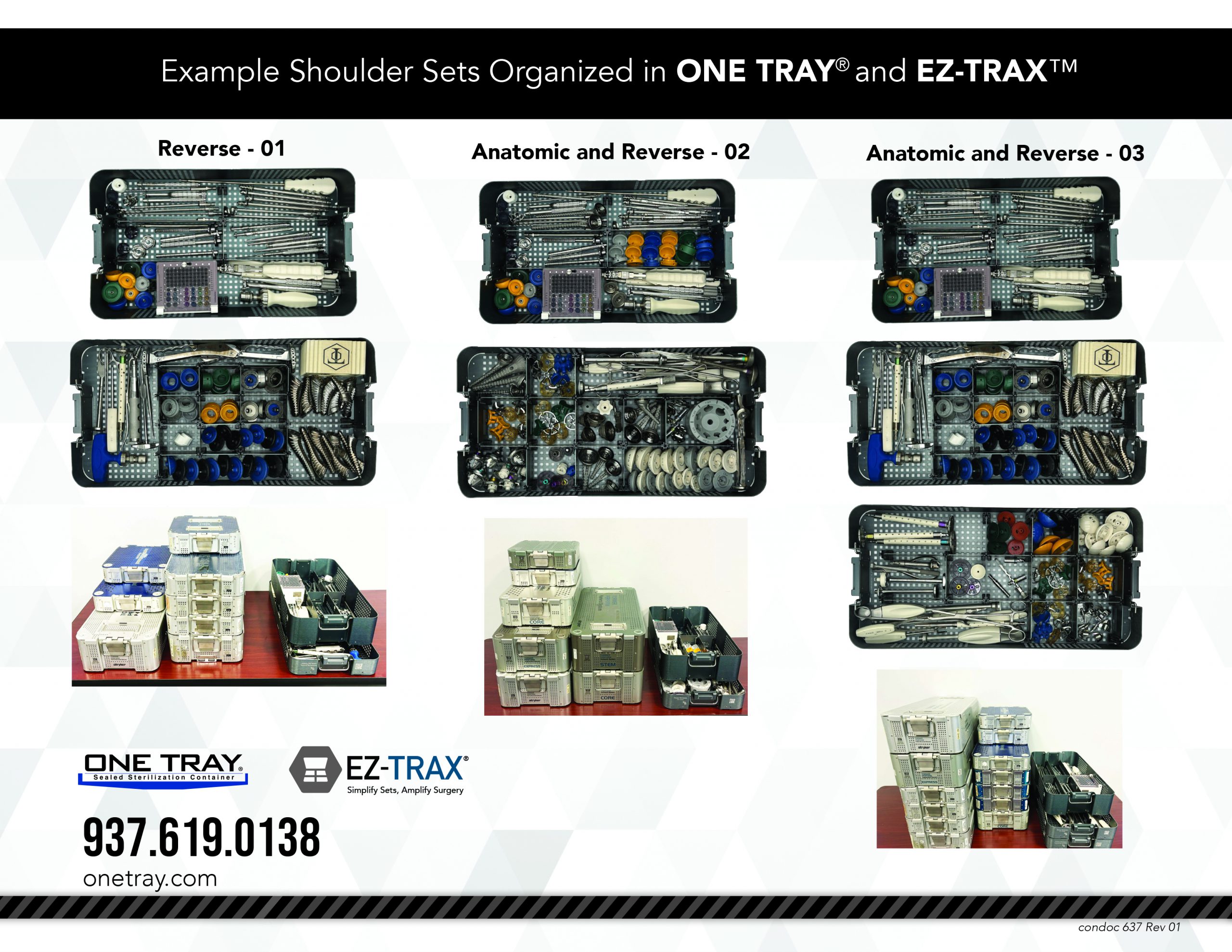

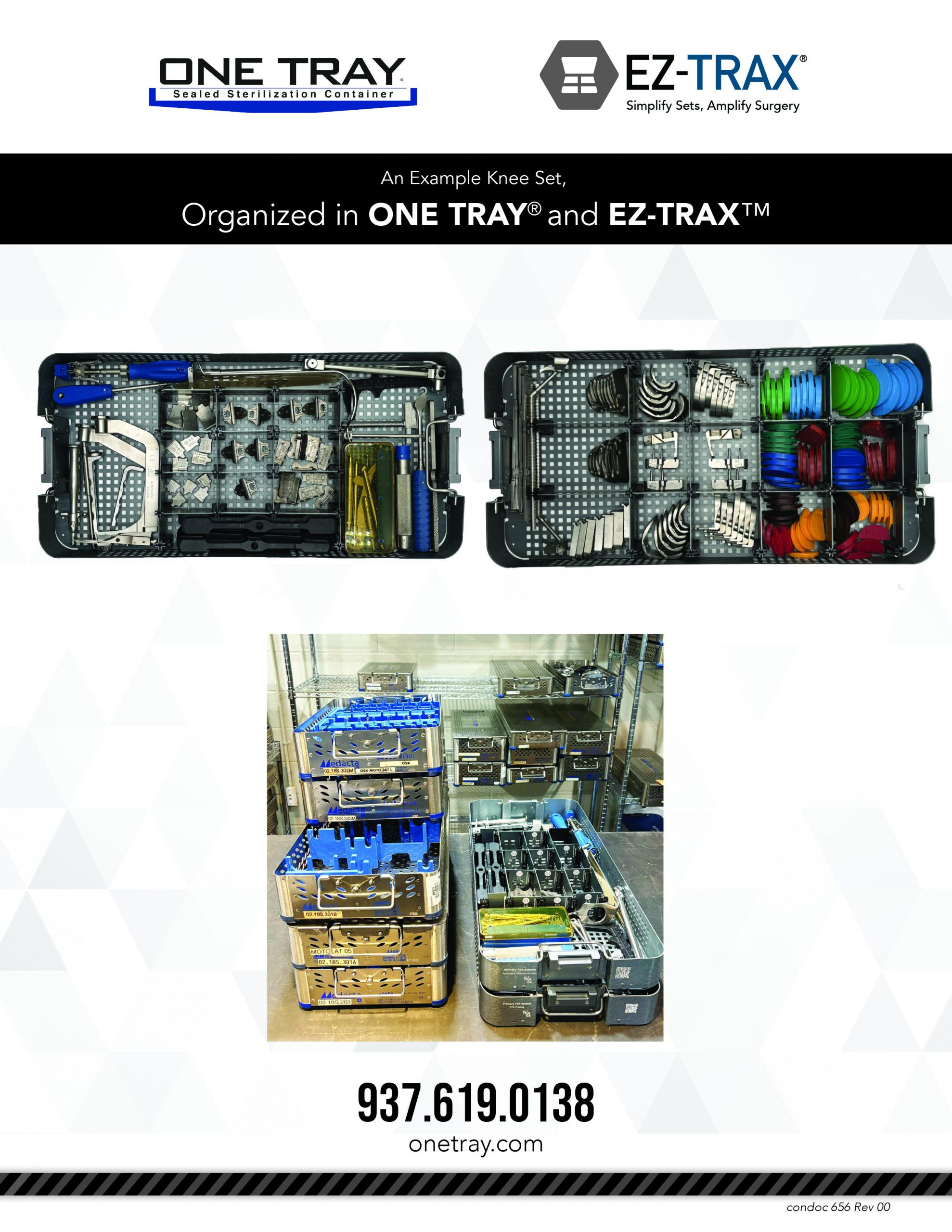

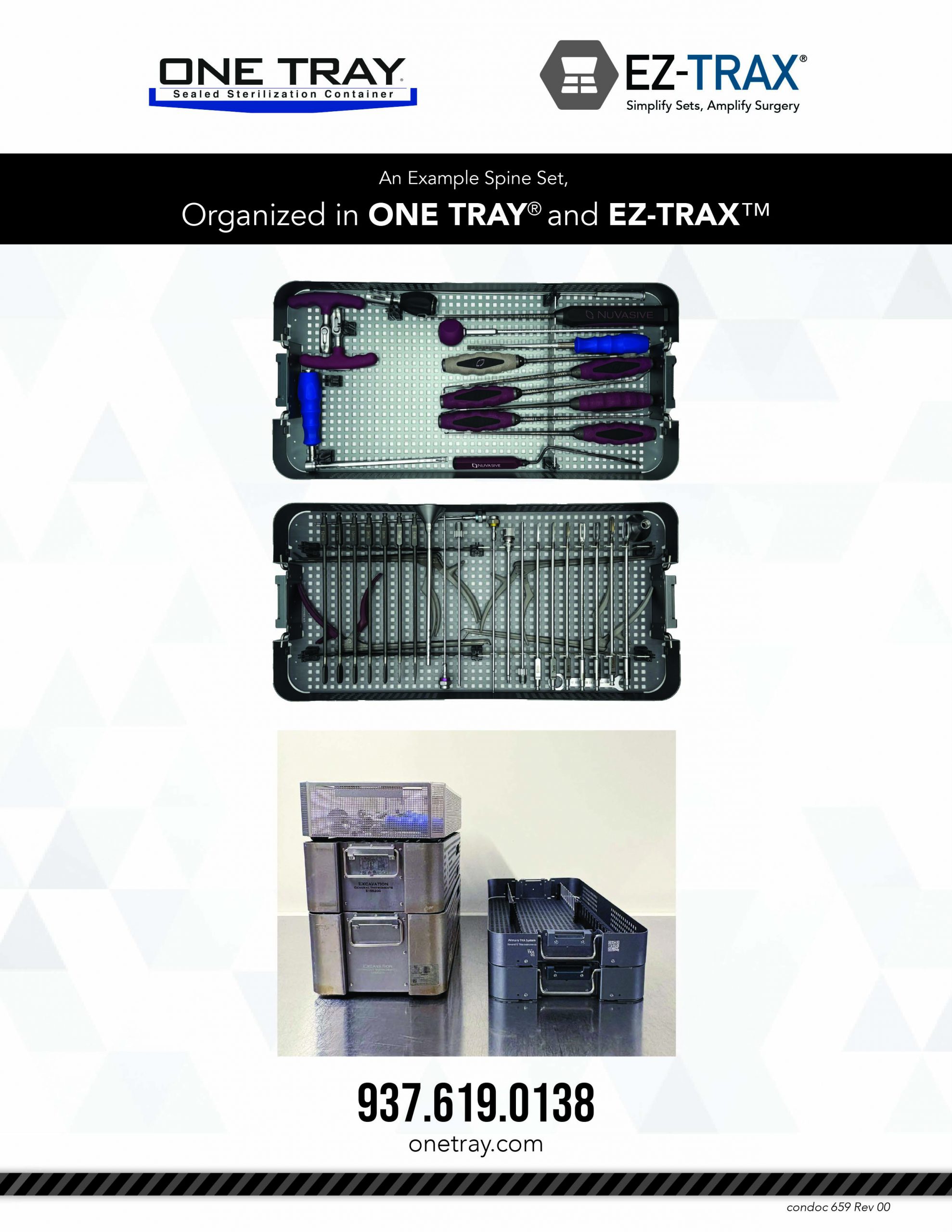

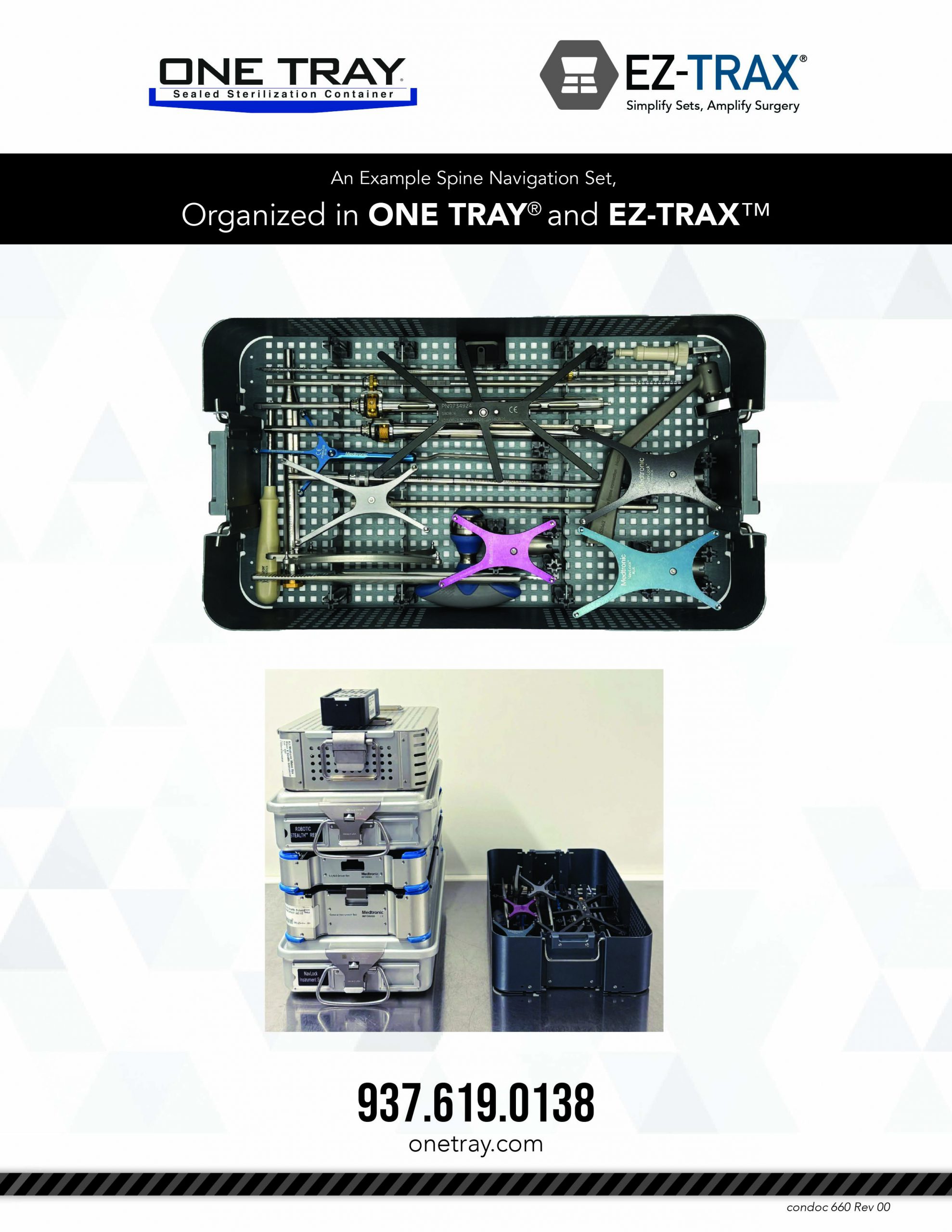

Reconfiguring bulky orthopedic instrument sets into EZ-TRAX™ trays brings clarity and efficiency to every stage of the surgical process. These streamlined layouts often result in over 50% fewer trays, reducing assembly time, washer cycles, and sterilization demands in the SPD while also minimizing tray openings and freeing up critical back table space in the OR.

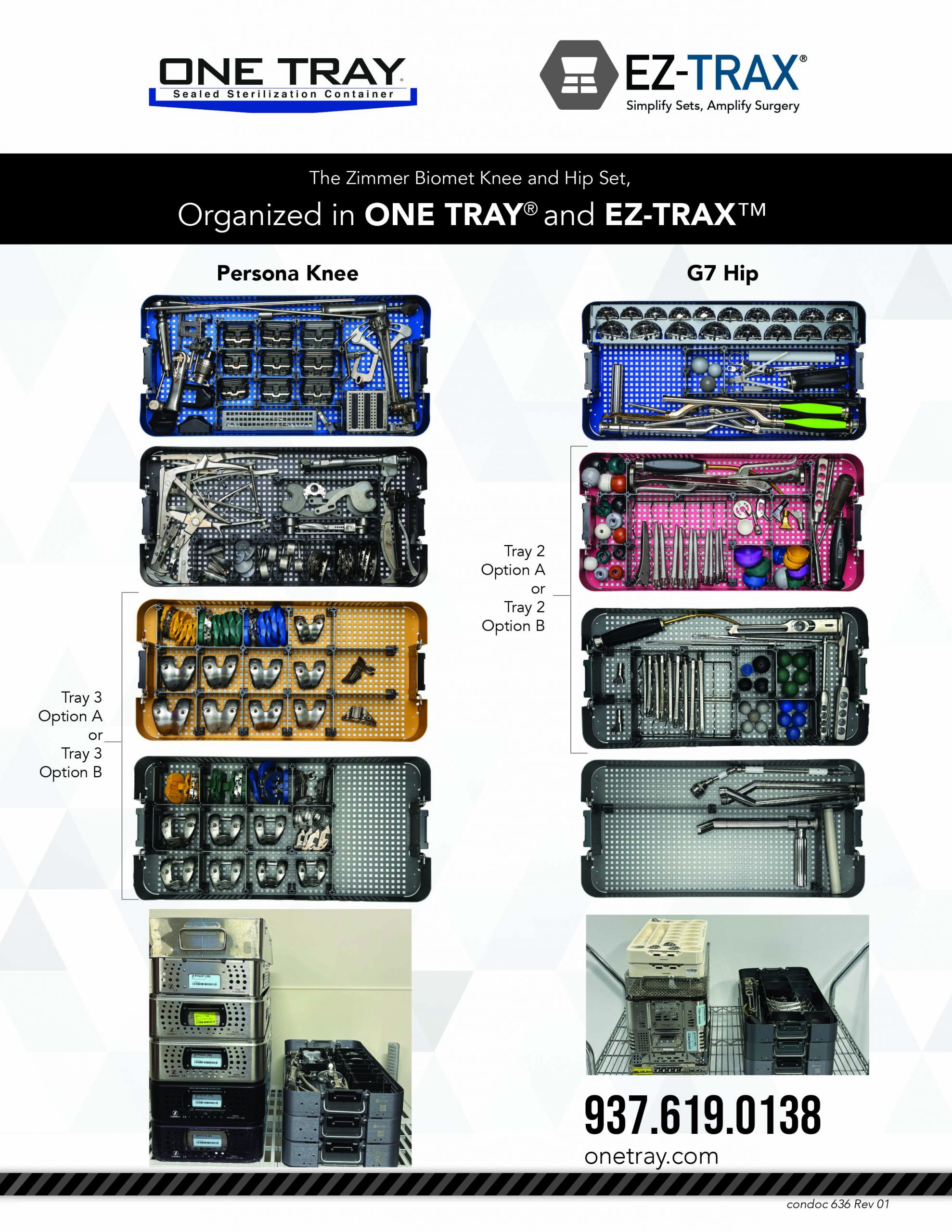

See the examples below to discover the impact of optimized organization.

A Testimony to the Power of Set Reconfiguration

Navigating 30 total joint cases in a day used to mean hauling in 5–6 trays per procedure for this facility, creating major challenges for set turnover, especially with limited sterile processing capacity.

By reconfiguring vendor sets and drastically reducing the number of trays per case, the team improved efficiency, minimized reprocessing delays, and empowered surgeons to increase their daily surgical volume.